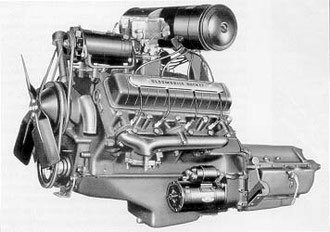

The 1949 Oldsmobile Rocket V8 set a new performance standard for mid-priced motoring. The motor displaced 303.7 cubic inches and produced 135 horse power.

Foreword

Author F. Gibson Butler participated in the creation of the first Oldsmobile Rocket V-8. Mr. Butler wrote this story in 1977 after retiring from Oldsmobile where he was a member of the postwar engine design group

The Rocket Engine Story by One Who Was There

by Gibson Butler

R. V. Hutchinson, who was an Oldsmobile engineer prior to transferring to Product Studies #5 when C. L. McCuen was appointed 1st Vice President in charge of engineering, designed and build a heavy in-line 6-cylinder (850 lbs.) spark ignition engine for high-compression studies. C. G. Kettering had request this design and build for G. M. Research Fuels and Lubricants department high performance number fuel/high compression ratio studies. The overhead valve engine was designed to operate at compression ratios up to 12.5:1.

The high-compression ratio engine studies resulted from the availability of triptane gasoline, a high performance number reference. T. A. Boyd, head of Organic Chemistry (later called Fuels and Lubricants) was instrumental in developing the isomerization of normal heptane to create triptane. This took place in 1941-42 as part of the War effort. In fact, G. M. Research built a small refinery in Redford Township to make triptane. Tank cars (one at a time) would be furnished by the Army/Navy at a very nominal cost for their aircraft engine research and development. The G. M. Research high compression engine studies received considerable publicity from the news media.

In the immediate post war period, Oldsmobile worked diligently to return to automobile production with the in-line "L" head 6- and 8-cylinder engines as power plants. The 1945-46 strike by the U. A. W. against G. M. delayed new car introduction and future engine designs. In January 1946, we were permitted to return to work in the engineering building (a number of us has worked at the Proving Ground with temporary design facilities during the strike). Upon returning to our Engineering Department, Gilbert Burrell, Chief Draftsman of the Motor Group, began to make a number of 3/8th scale layouts of various engine/driveline/vehicle concepts. Gilbert always retained a drafting board in addition to a desk for his own use. Gilbert Burrell's conceptual layouts considered swept-back bodies, square backs, two-doors, four-doors, etc. with in-line and V-8 engines. Always the 90-degree V-8 provided the best "packaging" as well as product potential. Gilbert was doing these layouts as a matter of personal interest rather than an assignment, his studies occurring while continuing to direct the efforts of the engine design men.

Burrell had been at his "private noodling" effort for five or six weeks without any interference when J. F. Wolfram, Oldsmobile Chief Engineer, stopped by to converse with him. Noting the drawings, Wolfram asked Burrell what he was doing. Together they went through the "stack." Impressed by the work, Wolfram invited Sherrod E. Skinner, Oldsmobile General Manager, to review the effort. Within the next day to two, Skinner, Wolfram, and Burrell thoroughly went over the carious conceptual designs and layouts. As a result, an advanced design group was set up with Burrell in charge. O. L. Anderson, George Jones, George Johnson, and Art Olmsted were among those assigned to this group. Their assignment was to design a new 90-degree V-8 spark ignition engine, a new chassis and vehicle concepts.

Anatole "Tony" Wouters, Carburetor Engineer, and I were requested to learn as much as possible about the G. M. Research (Kettering) high-compression engine studies. We held conversations with Daryl Caris and T. A. Boyd of G. M. Research, and R. V. Hutchinson and John Dolza of Product Studies #5 and #4 respectively. One additional conversation was arranged with C. L. McCuen, Vice President in charge of Engineering. Burrell also attended this meeting. McCuen was Motor Engineer at Oldsmobile during the development of the in-line 6, 8, and Viking V-8 engines. In fact, he and Gordon Bygraves of Lansing Pattern "worked out" the first integrally cast V-8 engine cylinder block; all previous V-type engines had been two-piece block castings bolted together.

Under Gilbert's leadership, design was initiated of a new 90-degree V-8 engine of 288 cu. in . displacement. This engine was called the SV-49. Immediately, Gilbert had John Coleman, Pete Mitchell, Marvin Katke, Frank Nethoway, and others of Production Engineering in consultation for the best possible product potential development.

In July 1946, Harold White, Motor Engineer, accepted a position with the Ford Motor Company engineering department. Gilbert Burrell was immediately appointed Motor Engineer. The Advanced design group was disbanded with the various men going back to their original groups.

SV-49 engine design and development accelerated and it appeared the first experimental engine would be ready to run in the fall of 1946. I spent three weeks at Product Studies #4 in late September and early October attempting to absorb as much engine knowledge as possible from men who had worked at Allison, Buick, Cadillac, and Chevrolet. The only major information I returned to Oldsmobile with was that Tony Wouters was leaving us on October 17 to go to Ford. The search was on for a replacement. A young man of about 30 years of age who had done some excellent work on the two-cycle Diesel at G. M. Research was recommended by Daryl Caris, Engine Research Head. He was interviewed and hired. His name - Elliot "Pete" Estes. Beginning his association with Oldsmobile Engineering in the latter part of November 1946, Pete immediately had an impact on our Motor Group.

Just about the time of Pete's arrival, the Motor Group gang gathered around the test stand in Elgin Neff's engineering assembly department. The first SV-49 was on the stand - coolant hoses were connected, battery cables connected, exhaust pipe connected - anticipation! Gilbert Burrell turned the ignition switch, the engine cranked over, it started. "The damn thing runs!" What an elated noisy bunch, a grand event in our lives, the birth had been successful. Four Sv-49 engines were build for laboratory studies and vehicle installation. It appeared we were on our way to entering a new dynamic era in Oldsmobile's automotive leadership.

Skinner and Wolfram requested approval and an appropriation from General Motors to produce our new baby. Disaster! Disappointment! Oldsmobile's request was rejected! Cadillac, builder of a 90-degree V-8 "L" head engine and beginning design of an overhead valve V-8, objected to any other division of G. M. building a 90-degree V-8. The objection stuck, at least temporarily.

Interest in our SV-49 cooled. However, we could not be defeated. Pete Estes and I began to look at the dynamics of other V-8 configurations. We studied an 8-cylinder 70-degree bank angle and one of a 60-degree angle with even firing. Concentrating on the 60 degree bank angle with even firing, we determined that the primary rocking couple could only be partially balanced with crankshaft counterweights and that a contra-rotating shaft with a counterweight at each end and rotating at crankshaft speed would also be required.

Together, Pete and I prepared a graph to show the imbalance and the counteracting requirements. Together we presented this to Wolfram who reacted emphatically against the need for an extra shaft with counterweights absorbing power and delivering no useful work of engine output.

Armed with this information, the next day Skinner and Wolfram made another trip to G. M. Central Office, this time to President C. E. Wilson. About midday, Burrell received a phone call from Wolfram, still in Wilson's office. Stop everything we were doing and begin working on a 90-degree V-8 engine immediately! The objections had been overcome. This was now March 1947.

Using our SV-49 experience, we immediately began the design of a 288 cu. in. 90-degree V-8 spark ignition engine was designated the 8-90 for engineering purposes. Production and processing engineers were called in immediately because machinery also had to be designed and built, plant layouts made to determine location and space requirements, suppliers were contracted - a hell of a lot to be accomplished in order to introduce the new "Kettering" engine in the 1949 model. But wait - "Who said you could name the engine Kettering? Don't you guys at Oldsmobile know that General Motors has a rule prohibiting the naming of any product after a living person?" Kettering was still active at this time. But we could name the plant the Kettering engine plant.

About this time, thermodynamic analysis and our SV-49 studies indicated that the engine should be somewhat larger. The displacement was increased from 288 cu. ci. to 303 cu. ci.

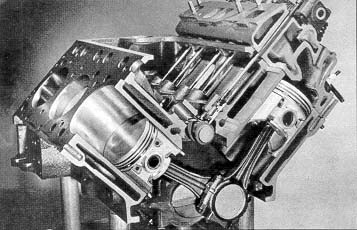

Cutaway view of the Rocket engine showing the over square design: bore of 3-3/4 in. and stroke of 3-7/16 in.

In the post World War II period, there was tremendous interest in rockets. Werner con Braun, the brilliant scientist/engineer, was brought to America with many of his associates. They had successfully developed the German V-2, used against the British Isles during the waning months of the war in Europe. This interest coupled with Oldsmobile's success in weaponry and shell manufacture inspired Skinner to name our new power plant the Rocket engine. We, in Engineering, thought the name stunk! How wrong we were! However, as everyone knows, the choice of name was excellent.

Engine development continued without letup. Hours and days became and amalgam without name. Coleman, Kolke, Mitchell, Estes, Burrell, Lunday, Anderson, Butler, etc. all huddled continuously, or so it seemed. Metzel, Kintigh, Wolfram all pressuring the experimental development. Meetings in the Dynamometer Lab office every morning. Finally we have an engine in a 78 model (the 88 designation came later). It's hotter 'n hell. Everyone is elated. We really got somethin'. Skinner was really happy! We will introduce it in the 1949 model. Skinner "leaked" the information about the hot new engine "those damn engineers have developed."

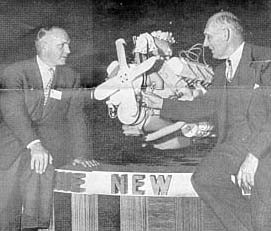

At the press preview announcement of Oldsmobile's new engine: Olds General Manager S. E. Skinner (left) and Charles F. Kettering, noted G. M. Research engineer.

Machinery was being received, the Kettering engine plant (the most automated modern engine facility in the world) was being readied. Pilot line production was scheduled for May 1948. We made it. The engine, no, the Rocket engine, became available with the 1949 model introduction in December 1948. The first all-new post World War II engine. The pattern for those which followed. Oh yes, Cadillac introduced its new 90-degree V-8 in the 1949 model also. However, it was the Oldsmobile Rocket that had captured the motoring public's imagination. Mr. Skinner, J. F. Wolfram, H. N. Metzel, L. A. Kintigh, Gilbert Burrell, Dave Ralston and other had outmaneuvered our sister division to the southeast. The American people were receptive, our Kettering engine plant was the talk of the industry, a new era had dawned that would enhance Oldsmobile's image for many years to follow.

Notes

The Rocket Engine Story Appended

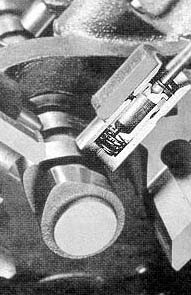

1. The Rocket engine introduced many new features, some of which were: a V-8 configuration with overhead valves, hydraulic valve lifters, a crankshaft with six counterweights (previous V-8s had eight counterweights, increasing inertia and decreasing performance), an "over square" design (bore diameter greater than stroke, providing rigidity and durability), and a full-flow oil filter

2. The Rocket engine, reduced to 288 cu. in. displacement, was equipped with 8:1, 10:1, and 12:1 compression ration cylinder heads by G. M. Research and sold to petroleum companies for fuel studies.

3. The Rocked engine was used extensively as an irrigation pump engine. Conversion to LPG was made by jobbers or equipment suppliers.

4. Dr. Flemming of G. M. Research developed a toroidal combustion chamber Diesel engine in 1953 using the Oldsmobile Rocket engine. This was the first successful "over square" Diesel engine (over square: bore diameter greater than stroke).

5. The Oldsmobile Rocket engine was used as a design standard by Chevrolet, Pontiac, and Buick 90-degree V-8 engines, many conferences were held with Burrell and his staff. As a result of Oldsmobile's experience, they were able to make design improvements i. e. sheet metal rocker arms eliminating the need for a rocker shaft, lighter weight cylinder block and cylinder head casting.

6. G. M. Truck used the Rocket engine for medium duty truck applications.

7. Many contributed to the success of the Rocket engine: From Oldsmobile Division, the major contributors were:

Sherwood Kinner, General Manger

Tom Downey, Manufacturing Manager

Earl Schuon, Comptroller

Dave Ralston, Sales Manager

Ed Warner, Public Relations

J. F. Wolfram, Chief Engineer

H. N. Metzel, Assistant Chief Engineer

L. A. Kintigh, Experimental Engineer

Gilbert Burrell, Motor Engineer and chief architect of the Rocket engine.

E. M. "Pete" Estes, Assistant Motor Engineer

H. H. Holmes, Chief Draftsman, Engines

John Coleman, Master Mechanic

and O. L. Anderson, F. G. Butler (the author), J. H. Lundy, T. R. Tompkins, L. T. Gill, George Miske, Hennig Rundquist, Carl Beck, William Holt, Elgin Neff, C. F. Hagen, Larry Becker, "Pete" Mitchell, Frank Nethaway, and Marvin Katke (first Kettering engine plant superintendent). Also Emil Zern and Joe Schneider of the Forge Plan, and Otto Henning of Carter Carburetor.

From G. M. Research: Art Underwood, Joe Bidwell, Tom Vandergrift, Egon Benesi, Charlie Gadd, Daryl Caris, Lloyd Withrow.

From G. M. Diesel Equipment Division: Bill Purchis and his staff who developed the hydraulic lifter. (Illustration at right)

Gordon Bygraved and the pattern makers of Lansing Pattern; the staff of Central Foundries; both supplier companies and G. M. Accessory Divisions were major contributors. Others whom I've forgotten or have not names. To those unnamed, I apologize.

Let's go Rocketing - Oldsmobile Rocketing that is!

F. Gibson Butler

November 15, 1977

Black Marilyn, ein 1957 Oldsmobile Golden Rocket 88

Black Marilyn, ein 1957 Oldsmobile Golden Rocket 88